Sustainability

Spearheading Sustainability through R&D

Reducing carbon footprint, Increasing Share of Renewable Energy

In terms of the share of renewable energy in power consumption, we are at a level of 55%, majorly due to our two off-site solar plants that have combined capacity of 10.7 MW. We plan to make incremental investments in solar projects to increase power generation through solar power by setting up more on-site solar panels.

It is the core philosophy of the company to ensure that our economic growth is socially and environmentally sustainable by implementing green chemistries and atom economy for efficient use of resources. Our emphasis on sustainable environmental practices and world class EHS (Environment, Health and Safety) measures have enabled us to achieve the below global certifications.

Significant Achievements in Sustainability

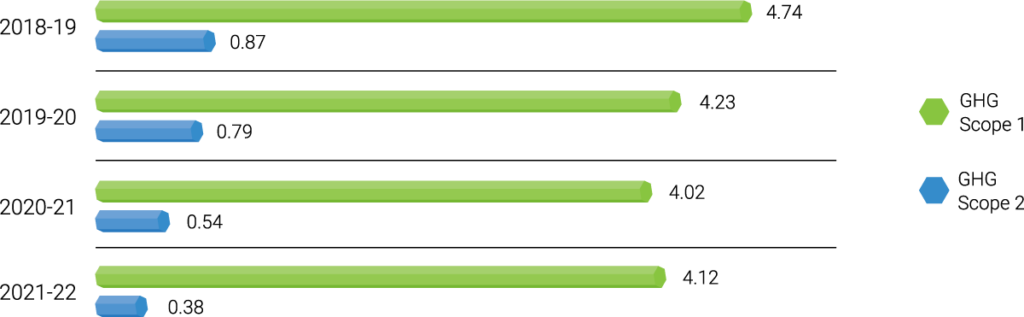

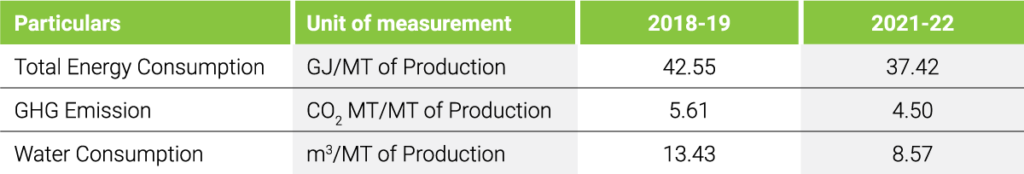

We have always been a responsible corporate citizen and given importance to sustainability while developing our chemistries used in manufacturing products. We focus on minimising the disposal of water, emissions and hazardous substances into the environment. We have implemented several sustainability initiatives that have helped in minimising environmental impacts of operations. Below is the status of our GHG emissions in MT/MT of production on a year-on-year basis

Achievements in Sustainability

We follow the ‘3R Process-Reduce, Recycle, Reuse’

Reducing freshwater consumption

We have built a robust rain water harvesting system to direct rain water to our underground water storage tank and filter and recycle it for internal consumption.

We are working on constantly optimizing plant processes to reduce water consumption in plant operations.

We are focusing on reducing process heat utilization thereby minimizing water evaporation losses and thereby reducing water consumption.

Minimising Waste Disposal

We have state-of-the-art Effluent Treatment Plants set up in all our three units. Through these plants, we have achieved ZLD status (Zero Liquid Discharge). We convert all our liquid effluent into clean water and recycle it back to our plants. For handling of solid waste generated in ETP, we have installed a Glass house in all our manufacturing units. We recycle & reuse almost all of solid waste generated across the Company

One of our key focus area is to continuously innovate processes to minimize waste and achieve best possible recycle & reuse of by-products generated. A strong in-house R&D team benefits us immensely in this effort. All our manufacturing facilities are fully compliant with regulatory approvals and are ISO 14001 and ISO 45001 certified.

We follow the ‘3R Process-Reduce, Recycle, Reuse’